Electrolytic Capacitor Definition

An electrolytic capacitor is a type of capacitor that uses an electrolyte to produce a higher capacitance than other types of capacitors. The electrolyte is a fluid or gel with a large number of ions. The high capacitive reactance of electrolytic capacitors has advantages and disadvantages.

Characteristics of Electrolytic Capacitors

They are characterized by high leakage current, equivalent series resistance, and limited service life. Electrolytic capacitors can be wet electrolytes or unidirectional polymer capacitors. They are usually made of aluminum or tantalum, but other materials can also be used. Most electrolytic capacitors have polarization, which means that the voltage at the positive electrode must be greater than the voltage at the negative electrode.

How Electrolytic Capacitors are Made

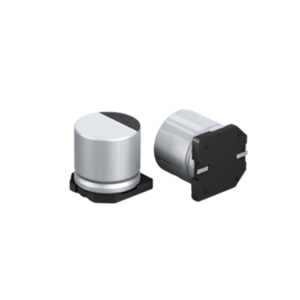

The figure above is the internal structure diagram of a commonly used electrolytic capacitor. Most electrolytic capacitors (also known as e-caps) are polarized capacitors that are mainly formed of two thin layers of metal foil and a paper spacer filled with electrolytes. A dielectric oxide layer acts as a dielectric medium – electrical insulation amid anode and cathode foil.

The supercapacitor is a unique electrolytic capacitor, usually called a double-layer capacitor. Their power range can range from hundreds of farads to thousands of farads.

The diverse qualities of oxide structures have an impact on the electrolytic capacitors’ following characteristics. Electrolytic capacitors with stable long-life properties, capacitors with low leakage current values, and e-caps with rated voltages up to roughly 100 volts all employ amorphous oxide anode foils. Capacitors with greater voltages, such as photoflash capacitors, frequently use crystalline oxide anode foils.

Electrolytic Capacitors Types & Applications

As one of the most important passive components, the electrolytic capacitor is a big family and has developed for nearly a century as a classic passive electronic component. Among the wide spectrum of e-cap, there are 3 kinds of them widely used in industry practice. They vary from each other in size, capacitance, and applications.

- Aluminum Electrolytic Capacitor

This kind of electrolytic capacitor has passed the longest period of design and manufacture, from the “Wet” type to the “Dry” type. They are named from the aluminum can which rolls up the anode and cathode and can be divided into the solid type and the non-solid type.

Nowadays, aluminum electrolytic capacitors are largely used in camera flashes, automotive airbags, power-factor correction, etc.

- Tantalum Electrolytic Capacitor

Tantalum capacitors are much more long-price than aluminum electrolytic capacitors. They produce low leakage with a high capacity and are often used with ceramic or film capacitors in power supply decoupling targets. Tantalum electrolytic capacitors feature a self-healing mechanism that functions to reduce MnO2 electrolytes into insulating Mn2O3. In addition, they behave superiorly stable in harsh environments (especially high-temperature ambient). - Niobium Electrolytic Capacitor

The niobium capacitor is relatively a young competitor in the market for the tantalum capacitor. They have a thicker dielectric layer and a lower breakdown voltage than tantalum capacitors. Besides the self-healing mechanism of tantalum capacitors inherent, niobium capacitors have one more feature: a self-arresting mechanism. The mechanism operates to protect the chip from short circuits fault on account of local breakdown. What’s more, they excel in resisting vibrations and shocks. Niobium electrolytic capacitors favor their used in consumer, industrial, automotive, aircraft fields, and so on.

Why Choose Electrolytic Capacitors

An electrolytic capacitor can adapt to higher frequency circuits than a usual ceramic capacitor can do because of its high capacitance values. Besides, they do a better job than super-capacitors in handling ripple current. And they are built to low volume which saves lots of space on a board, saving direct cost.